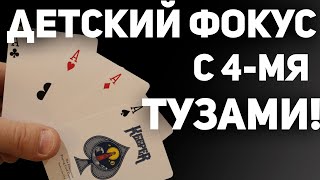

Here is another video (clear, and I cropped it down) my turbo actuator on my BEW engine cycling the N75 through VCDS software. I have performed 3 Mr. Muscle oven cleaner treatments on different days to free up sticking vanes. The actuator moves freely and smoothly (no sticking) when rod is moved manually as well as with a manual vacuum pump. I have confirmed -22inHg from my engine vac pump and -22inHg to 0inHg between n75 and actuator (snappy/instant vac pressure and release when cycled). Again, when actuator is pumped manually full movement at full pressure is achieved and the spring gives good snappy movement at 0inHg when vacuum is released. I gather that this means good movement in turbo vanes, good actuator, good n75 solenoid, good vacuum pump, no leaks in vac lines. What could possibly be my problem? I'm still getting P0234 code and you can see actuator is not moving well/at all.