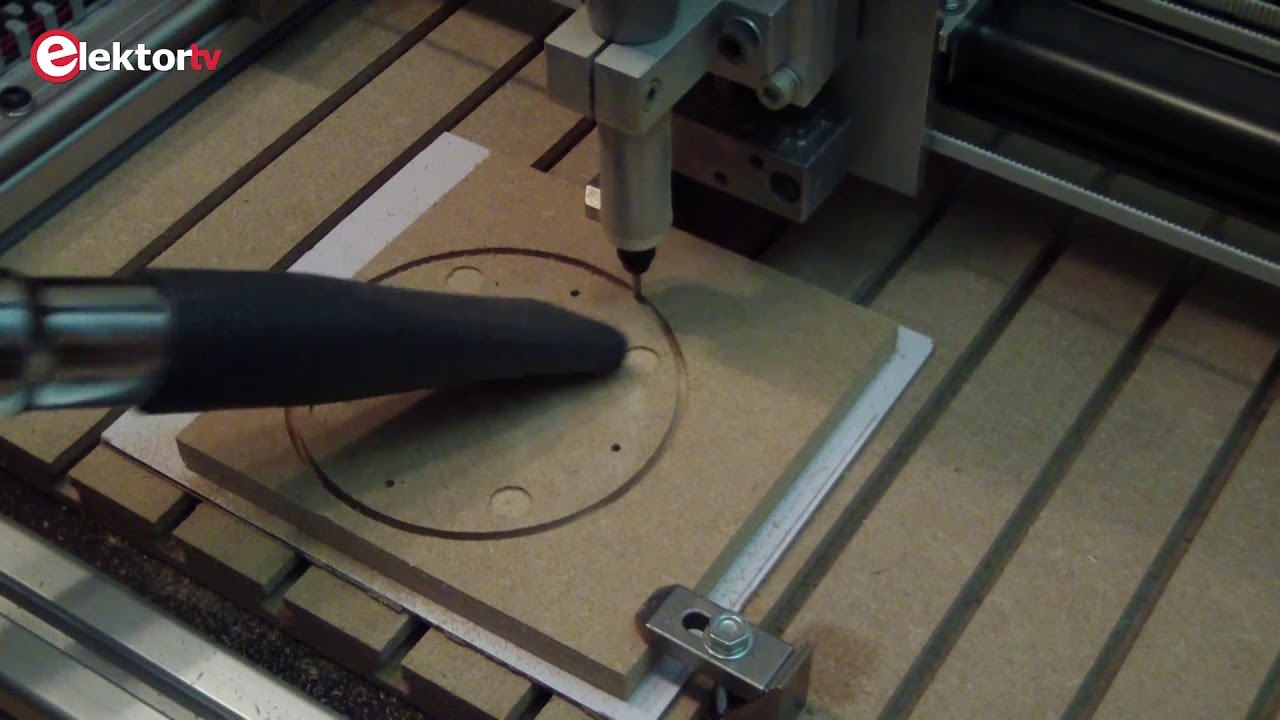

This CNC gantry robot shows the results of our efforts to build our own little CNC machine from scratch. A detailed description of it can be found in Elektor Magazine:

- part 1: issue 3/2019, page 52, [ Ссылка ]

- part 2: issue 5/2019, page 26, [ Ссылка ]

- part 3: issue 11/2019, page22, [ Ссылка ]

This video shows a compilation of some tests we carried out with the machine and some results we achieved. Please note that this is a prototype and that the project is subject to change.

Software used:

* Eding CNC Starter Software Release for CNC310

* DraftSight

* EstlCAM

Some specifications:

• work surface area about 50 × 30 cm

• linear glides with polymer bearings, insensitive to contamination

• maximum speed of X and Y axes: 15000 mm/min, Z-axis: 750 mm/min

• repeatability: about 0,2 mm

• nema-17 stepping motors

• driven via reinforced GT2 toothed belts (X and Y axes) and screw spindle (Z-axis extension)

• Z-axis extension suitable for drilling, milling and engraving in wood, plastics and non-ferrous metals (aluminium, bronze).

Using Proxxon LBS/E spindle (5,000 – 20,000 rpm, 100 W)

• professional drivers and software from Eding CNC (cnc310 controller board)

• stepping motor drivers based on Trinamic TMC2160 controller IC’s for silent operation

• 2.5D software extendible to full 3D

• multi-functional design, can be extended for other applications

• can be extended with a pendant (= console with buttons and wheel for manual control)

• maximum power consumption without drill/grinder: about 100 W

• total mass of the machine including Z-axis extension and Proxxon LBS/E drill/grinder: 24 kg

![8 HACKERS que CAMBIARON el MUNDO [RECOPILACIÓN]](https://i.ytimg.com/vi/8PN58BEusbE/mqdefault.jpg)