#electrical_engineering #overload_setting #engineering

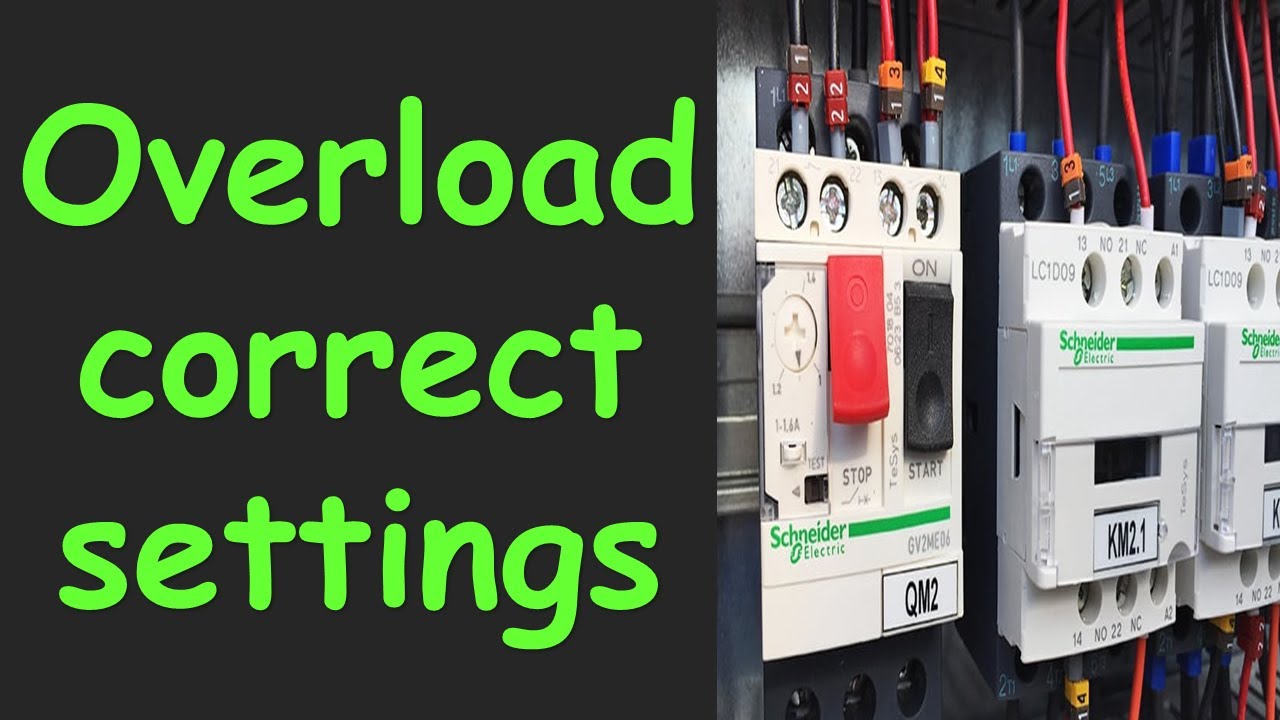

We have these three motors, and we need to calculate the correct overload settings for each one.

First check the service factor for each one.

The service factor is a measure of periodically overload capacity at which a motor can operate without damage.

A motor operating continuously at a service factor greater than 1 will have a reduced life expectancy compared to operating at its rated nameplate horsepower.

This motor has a service factor of 1.3, which is a hundred and thirty percent, so we are saying that it can run at about a hundred and thirty percent for short durations without causing major damage to the motor.

The second motor its service factor is 1.1 or about a hundred and ten percent.

And then our third motor here is not marked, we will discuss later what we will do if the service factor is not marked.

For marked service factors of 1.15 or more, we are going multiply the full load current rating of the motor by a hundred and twenty five percent.

For service factors less than 1.15, we will multiply the motor full load rated current by 1.15.

Theses calculations will give us the maximum settings for the overload protection devices.

For the motors with unknown service factors, we will assume that it is 1 or hundred percent, so it falls into the category of less than 1.15.

So, the maximum overload setting for unmarked service factor motor, it will be the multiply of the full load current by 1.15.

Now let’s apply it to our three individual motors.

For this motor we have a marked service factor of 1.3, and a full load current of 42 amps, so according to our calculations, the maximum overload setting for this motor will be 44 amps times 1.25.

So, it should give us 55 Amps, and it is the maximum calculated overload setting for this motor.

Our second motor is 30 Amps full load current and a service factor of 1.1.

So, it falls into the category of 1.15 or less service factor.

We will multiply the 30 amps by 1.15.

The maximum overload setting for this motor will be 34.5 amps.

The third motor does not have a service factor marked so again as mentioned here, if it’s not marked, we’re going to assume a service factor of 1,

If we have a service factor of 1, we will multiply the full load current by 1.15.

So, the maximum overload setting for this motor will be 28 amps multiply by 1.15, and it will be 32.2 amps.

If the motor is starting through a star delta circuit, which means that our motor is going to start on star configuration, and then once it gets up to a certain speed or a certain duration of time has passed, it’s going to switch into delta configuration, and it’s going to run in delta.

That means, when we’re sizing the overloads, we must consider the location of the overload in the circuit, for star delta circuits the overloads are located within the phases, so we will size the overload based on the phase current of this motor.

So, for a 40 amps full load current motor, the 40 amps represent the line current, and we know that there is a root three relationship between the line and the phase currents, or we can say that the phase current is equal to the line current multiplied by 0.577.

In our case it should be around 23 amps.

Let we assume that the service factor for this motor is 1.2, so it is into the category of service factor of 1.15 or more.

The maximum overload setting for this motor will be 23 amps multiplied by 1.25.

It should be 28.75 amps

Thank you for watching.

How to set the overload correctly?

Теги

ElectricalPowerMotorsubstationtransformeroverloadoverload setting for 3 phase motorsoverload setting for star delta starteroverload settings for motorscontrol circuit diagramcontrol circuit explainedcontrol circuit of star delta startermotor protection relaymotor protection circuit breakermotor protection devicemotor protectionservice factor on motorsload current calculationmpcb settinglearn eeethermal overload relay in hindioverload relay