Viva Energy’s Geelong Refinery experienced significant and dynamic flue gas line afterburn downstream of the FCCU, requiring frequent operator intervention. Ultimately this caused the refiner to reduce rates by almost 10% for certain feedstocks, impacting overall refinery economics by tens of thousands of dollars per day.

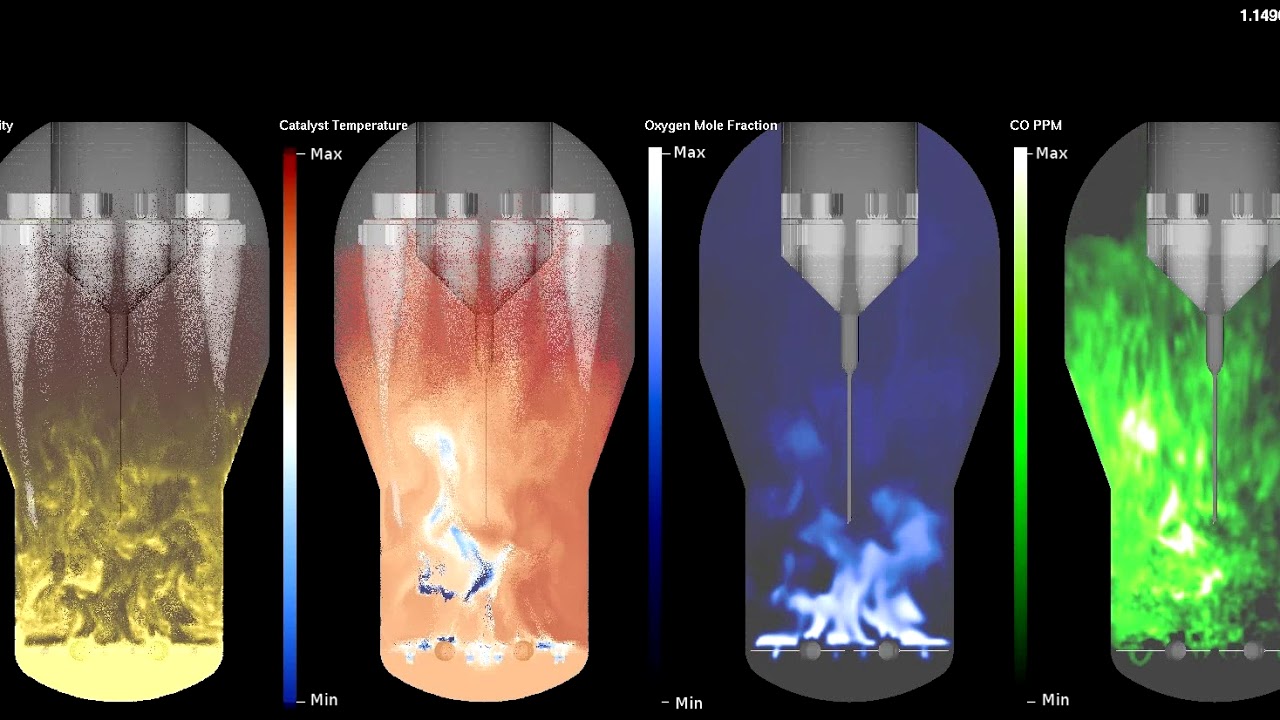

This video shows the hydrodynamics, thermal profile and effect of combustion reactions in the FCC regenerator. Maldistribution of spent catalyst causes significant CO on the west side of this full-burn unit, which combusts with the excess oxygen when mixed in the flue gas line. Learn about how the Geelong Refinery used Barracuda Virtual Reactor to reduce turnaround risk in identifying and correcting the problem as published in the September 2018 issue of Hydrocarbon Engineering.

Visit www.CPFD-Software.com for more info!