Καλά κολλήματα, και δεν ξεχνάμε το γρασάρισμα, ανάλογα με τα κιλά που θα έχει η καρότσα, κάνουμε και τον μύλο, μέχρι 500 κιλά 6 χιλιοστά αντέχουν, σας ευχαριστώ

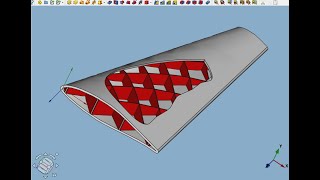

A two axle trailer needs to have some kind of mechanism in the front axle, that allows it to turn and tilt at the same time, in order to properly stear the trailer and take up the road bumps. It also needs to be strong to hold the loads of the trailer.

This mechanism can be made from thick metal, 6 or 8mm thick, using the stensils I cut out from cardboard.

You'll need two discs, about 20cm in diameter and 6 or 8mm thick. This size is able to stand loads of up to 300 - 400 kilos.

For higher loads you'll need to widen the diameter.

One disc will be smaller than the other, because it will be housed inside the bigger disc. The bigger disc will be the outer case of the pivot mechanism. The part that will be welded on the trailer's undercariage.

You will also need a metal stip at least 20mm width and 5 or 6mm thick. This strip will form the wall around the outer case and It will enclose the smaller disc.

Finaly you'll need a metal ring roughly the diameter of the big disc, to form the underside of the pivot. This ring will be welded on the metal sidewall of the pivot, enclosing the small disc and working as a retainer for the axle, in case for some reason the whole mechanism is lifted off the ground.

The middle disc, the smaller of the two, will be the operating part of the mechanism. So it will have the axle attached to it. To attach the axle we'll need to weld thick metal pieces, parallel to each other, exactly at the center of the disc. You can measure and weld these pieces even before placing the inner disc in it's position in the mechanism.

These two center pieces will have holes in them, to allow for a pin through them. This pin will be holding the axle in place and needs to be sturdy. 10 or 20 mm diameter pin is a good size. It will pass through the center point of the axle and allow for it to tilt left and right, around the longitudinal axis. This way the wheels will absorb the pitholes on the road. At the same time, the pivot disc will be taking up the turning movement of the axle left and right.

So effectively this mechanism will be able to hold the weight of the trailer, turn left and right around the vertical axis, and also allow the axle to move around the longitudinal axis.

You will need to drill a peep hole on the top disc, (the big one) for greasing the smaller pivoting disc through it.

Remember to make your welds as good as possible, because the loads will be high, and don't forget to apply the grease through the peep hole.

We can make the mechanism according to the load we're planning to apply on the axle, adding a small safety margin of course. For loads of up to half a ton, 6mm thickness is enough. You can make the diameter even wider than 20cm.

Thanks for watching, and if you like what you see, consider subscribing.

![Харун Яхья - РАЗВРАТНАЯ СЕКТА турецкого креациониста - Аднан Октар [История культа]](https://s2.save4k.su/pic/wpBxPqZXEoI/mqdefault.jpg)