More information about the KAN-therm Copper system ▶ [ Ссылка ]

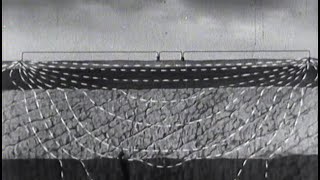

KAN-therm Copper uses the "Press" technology which provides a secure and quick joint by pressing fittings on a pipe.

The assembly is done with generally available crimping tools, eliminating the screwing or soldering process of individual elements.

The fittings of KAN-therm Copper system are made of high-grade Cu-DHP copper and bronze.

Assembling system elements in the "Press" technology allows making joints with minimum pipe cross-section narrowing, which considerably reduces pressure loss in the entire installation and results in excellent hydraulic conditions.

Tightness of assembling in KAN-therm Copper system is guaranteed by special O-Ring sealing and an "M" profile clamp made in three main points of a fitting.

Application possibilities:

— Drinking water installations

— Heating installations

— Cooling installations (closed or open)

— Compressed air installations

— Solar and heating oil installations

Advantages:

— Quick and easy connection technology – "Press"

— The most popular on the market, highly accurate three-point M crimping profile

— Quick and reliable assembly, without soldering or screwing

— Wide diameter range 12-108mm

— LBP function – in the whole diameter range

— Special fitting design for easy pipe fastening

— High resistance to corrosion

— No fire hazard during installation and operation

— Highest aesthetics of the finished installation

LinkedIn ▶ [ Ссылка ]

Instagram ▶ [ Ссылка ]

Facebook ▶ [ Ссылка ]

KAN-therm Copper assembly Ø12-108 mm EN

Теги

kankan-thermsystemy kanassemblykan-therm assemblyunderfloor heating manualadvantages and disadvantages of underfloor heatingambiente underfloor heatingaverage cost of underfloor heatingbathroom underfloor heatingbeneath heat underfloor heatingbenefits of underfloor heatingbest electric underfloor heatingfloor coolingfloor heat solutionsfloor heatingcopperkan-therm copperkantherm coppercopper tubescopper pipes

![AI Generated sci-fi future cities art - Technical Evolution - AI Generated Images [AI Generated 21]](https://s2.save4k.org/pic/Lc06NH_9GF0/mqdefault.jpg)