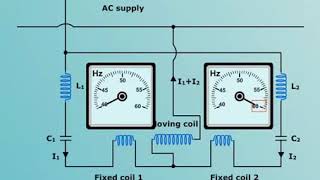

Rotary motion to Linear motion mechanism (advancing perforated strip) ✅📌#RotaryToLinear#MotionMechanism#RotaryMotion#LinearMotion#Mechanics#MechanicalEngineering#EngineeringDesign#Kinematics#CamAndFollower#LeadScrew#RackAndPinion#MechanicalSystems#AutomationTech#MotionControl#engineeringinnovation

@Er_Simmu1014

Rotary-to-linear motion mechanisms are systems that convert rotational (circular) motion into linear (straight-line) motion. These mechanisms are widely used in various machines and devices, from simple mechanical systems to complex industrial machines. Below are some common types of mechanisms that perform this conversion:

1. Lead Screw (or Power Screw)

Description: A lead screw uses a threaded shaft and a nut. As the screw rotates, the nut moves along the screw’s axis, converting the rotary motion into linear motion.

Applications: Used in vises, clamps, jacks, and CNC machines.

2. Rack and Pinion

Description: This mechanism consists of a circular gear (pinion) that engages a flat gear (rack). As the pinion rotates, it moves the rack in a straight line.

Applications: Used in steering systems, linear actuators, and railway switches.

3. Cam and Follower

Description: A cam is a rotating or sliding piece in a mechanical linkage that transmits motion to a follower, which moves in a linear path. The cam’s shape dictates the movement pattern of the follower.

Applications: Used in engines, printing presses, and automated machines.

4. Crank and Slider

Description: This mechanism consists of a crank (rotating part) connected to a slider (moving in a straight line). As the crank rotates, it pushes or pulls the slider, converting rotary motion to linear motion.

Applications: Found in piston engines, pumps, and compressors.

5. Belt and Pulley with Linear Guides

Description: A belt running over a set of pulleys can drive a linear guide when tensioned properly. The rotational motion of the pulleys moves the belt, converting to linear motion.

Applications: Used in conveyor belts and certain types of automation systems.

6. Ball Screw

Description: Similar to a lead screw, but with ball bearings in the nut to reduce friction. This allows smoother and more precise linear motion when the screw rotates.

Applications: Precision machinery, robotic arms, and linear actuators.

These mechanisms are fundamental to robotics, automation, automotive systems, and industrial equipment machines.