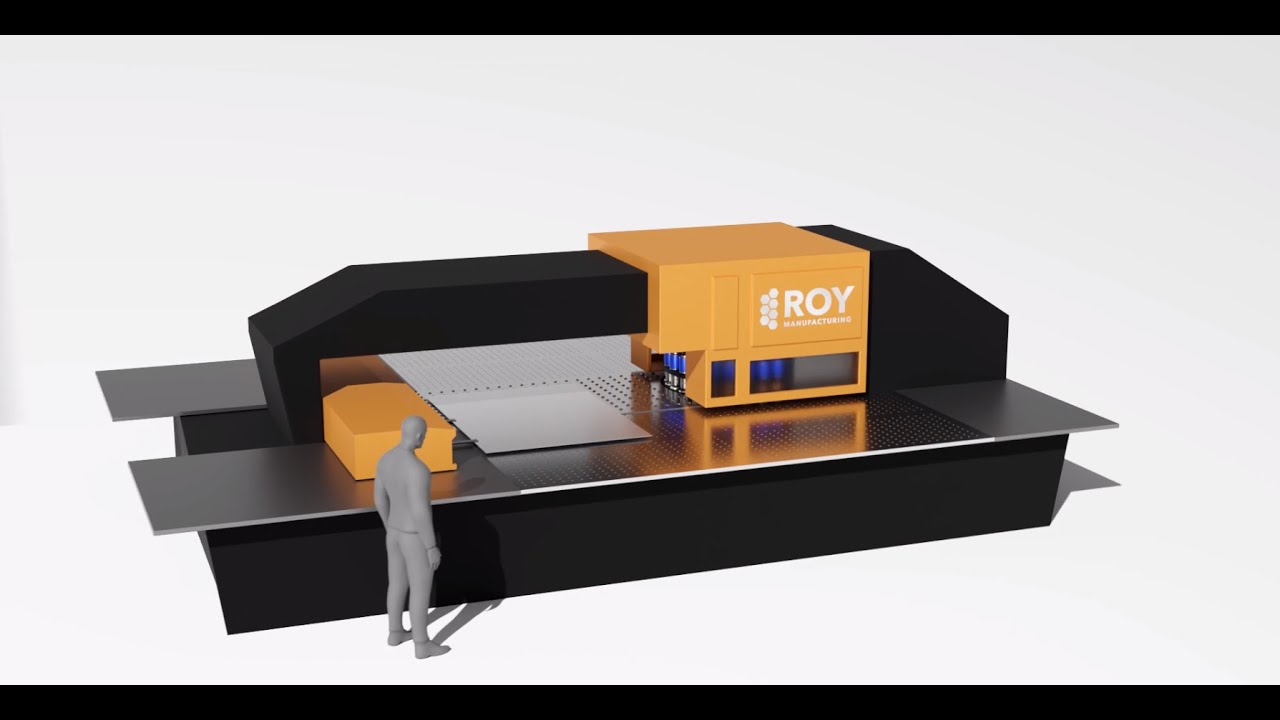

A turret punch press is an advanced computer numerically controlled or CNC machine used to transform large sheets of material into intricate screens.

It consists of two rotating wheels or turrets that work together to create precise holes. The upper turret holds up to 60 punch tools, while the lower turret holds corresponding dies.

As the turrets rotate, they position the appropriate punch tool and die under the striker plate, ready to execute the pattern. The material moves under the press, while the punch tool and die remain stationary.

The press exerts tremendous force as it descends, punching the tool through the metal and into the die, creating flawless holes or patterns.

A spring lifter quickly raises the punch tool for the next strike. The machine's speed can be adjusted for optimal performance. Multiple trips under the press may be required for complex designs, allowing for greater precision with each trip.

Roy Manufacturing's CNC punch presses offer precision, efficiency and unmatched craftsmanship, producing industrial and architectural components that surpass expectations.

![Polyvox CM 5000 pre amplificador system 5000 [ demonstração]](https://i.ytimg.com/vi/wvQzDIvjAks/mqdefault.jpg)

![Request ✨️👑 [I chose Caspian, cause I have other Ben edit ready] #princecaspian #benbarnes #narnia](https://i.ytimg.com/vi/NEQW0gnfK3Y/mqdefault.jpg)