Check out 3D OCD!

[ Ссылка ]

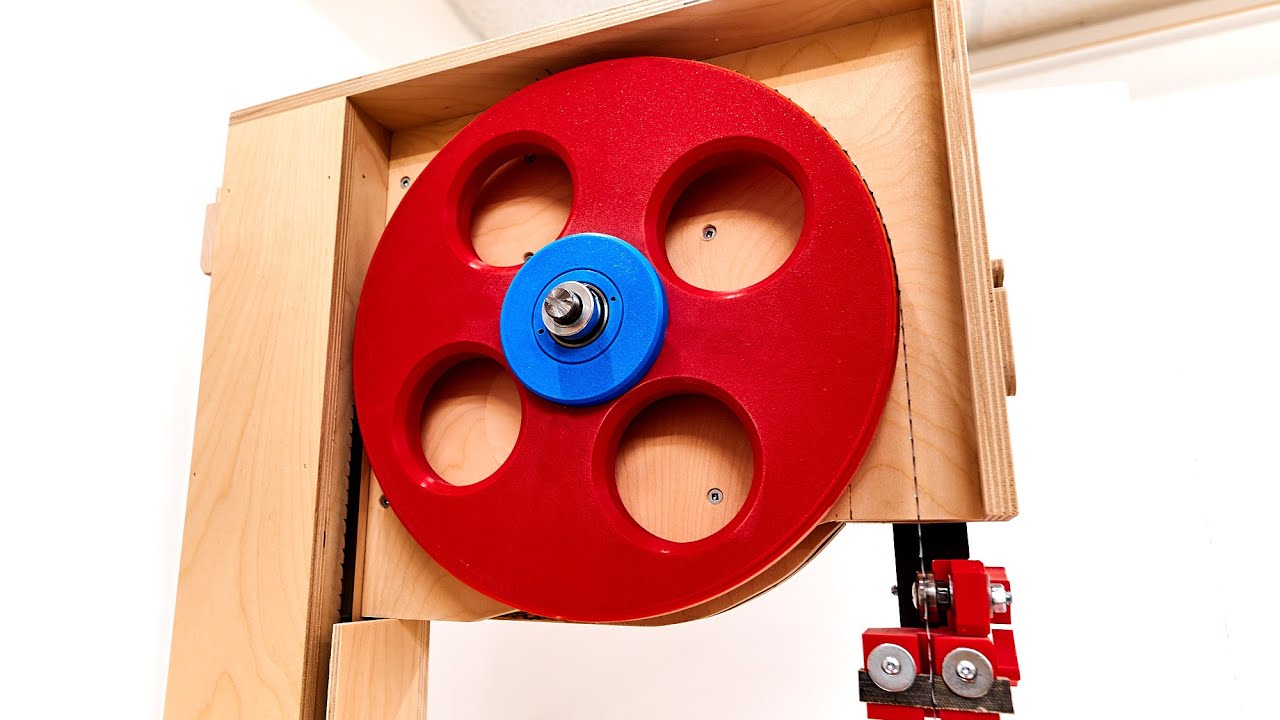

The next band saw challenge is to make probably the most complex and intimidating parts on a homemade machine, the wheel. It has to be:

- precise and a 3D printer can do that easily

- balanced which is hard to do with wood (but easy with 3D printing)

- have a slight crown on the rim to make the blade track properly. Again easy to design in with a 3D printed wheel, but difficult to do when making it from wood

- strong and that was the question I answered in this video. The 3D printed wheel is absolutely strong enough even when left under tension for an extended period.

I printed the wheel in 10 pieces - 8 wheel segments and two hubs that took almost 20 hours to print.

The mistake I made that caused the wheel to wobble was having too much clearance around the alignment pins that fit into the holes in the wheel. A better way would be to either make it a tighter fit or make it so that it can be adjusted, i.e. bolted together rather than glued.

But wobble haw no effect on performance so a small amount is perfectly fine.

#3dprinting #bambulab

▶️ Project plans for sale: [ Ссылка ]

▶️Support the work I do on Locals:

[ Ссылка ]

▶️ Patreon:

[ Ссылка ]

▶️ Join my Makers Mob for detailed build tutorials:

[ Ссылка ]

My "Scrap bin" channel:

[ Ссылка ]

#ibuildit

#woodworking

Website: [ Ссылка ]

Facebook: [ Ссылка ]

Instagram: [ Ссылка ]