Get the Files for The Cup: [ Ссылка ]

Get the Liner for the Cup: [ Ссылка ] (Make sure to get the silver one)

As an Amazon Associate I earn from qualifying purchases.

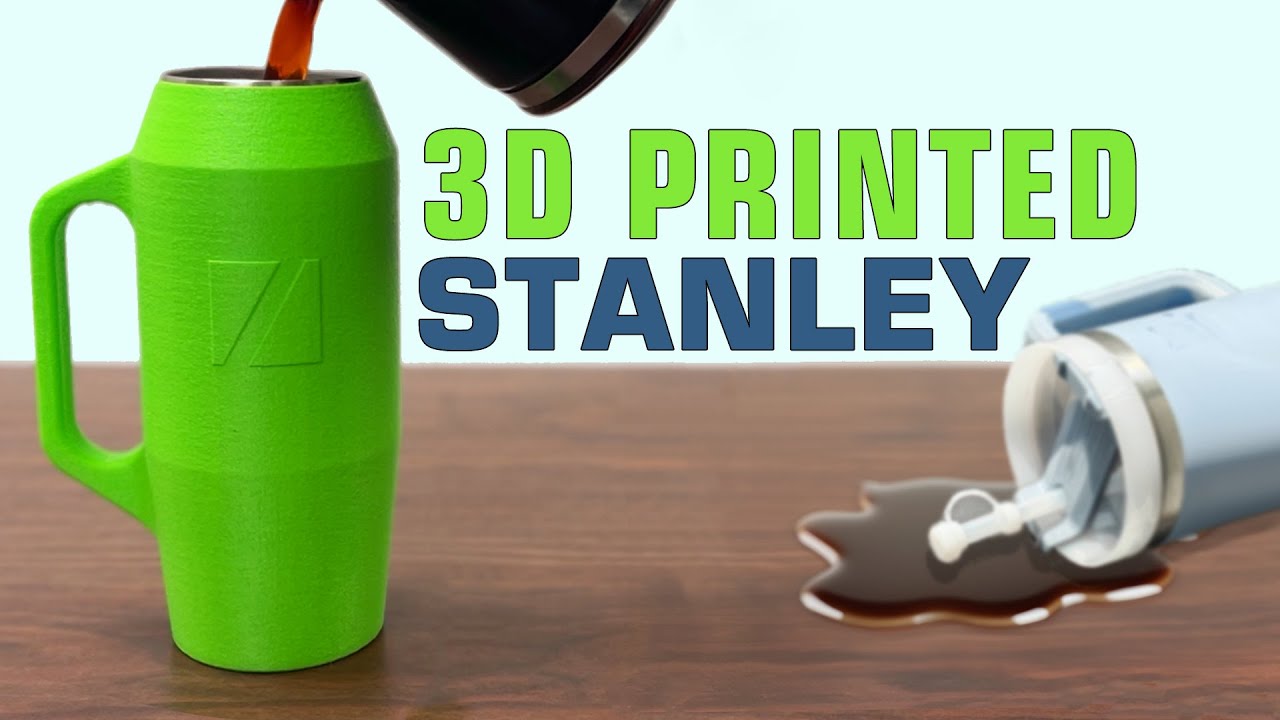

In this episode of Design for Mass Production 3D Printing, we design a Stanley Cup tumbler completely optimized for 3D printing.

We discuss how 3D printing technology allows us to create a tumbler that's not only aesthetically pleasing but also offers impressive insulation and durability. Learn about the design process, from the initial concept to the final product, showcasing the capabilities of 3D printing in creating customizable, durable, and innovative consumer products. Get a behind-the-scenes look at the secret sauce that makes our 3D printed tumbler stand out, including its stainless steel liner for easy cleaning and unique insulating properties. Whether you're a coffee aficionado or a technology enthusiast, this video will change the way you think about how we manufacture everyday products.

About Slant 3D

🏭 High-Volume 3D Printing: Scalability Meets Flexibility

Slant 3D's Large-Scale 3D Print Farms utilize 1000's of FDM 3D printers working 24/7 to offer limitless scalability and unparalleled flexibility. Whether it's 100 or 100,000 parts, our system can handle it reliably, while still allowing for real-time design updates, ensuring products evolve with the times. This adaptability is key in today's fast-paced world.

🌿 Sustainable Manufacturing: Eco-Friendly Efficiency

Embrace a system that drastically reduces carbon emissions by eliminating carbon-intensive steps in the supply chain, such as global shipping and warehousing. Our approach minimizes this footprint, offering a more sustainable manufacturing option.

⚙️ Digital Warehouses: Parts On-Demand

Think of print farms as a "Digital Warehouse", meaning we can store your parts digitally on a server rather than physically on a shelf. parts are available on-demand, reducing the need for extensive physical inventory.

LEARN MORE at [ Ссылка ]

Produced by Slant Media