Check it Out!

Today we'll be working on a log splitter that needed a flywheel replacement due to the engine over revving (caused by a governor linkage failure).

The flywheel nut needs to be torqued to 70-80 NM (Newton Meters) which is approximately 55 ft-lbs.

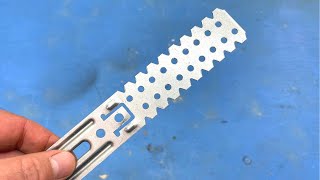

To achieve this torque, we need to somehow prevent the new replacement flywheel from rotating.

On a riding mower, or even a push mower, this can be done by putting a socket on the pulley bolt or blade bolt on the other side of the engine.

However, on this log splitter, there's a hydraulic pump on the other side of the engine, so how do we prevent the flywheel from spinning without damaging our new flywheel?

Watch the video to find out!

_______________________________________________

If you enjoyed the video, hit LIKE & SUBSCRIBE!

New videos every week!

Get up to 3 Months FREE NordVPN with this sign up link; [ Ссылка ]

Lube-Shuttle: [ Ссылка ] (Promo Code ELIMINATOR for 5% OFF)

SOCIAL MEDIA:

[ Ссылка ]

[ Ссылка ]

[ Ссылка ]

[ Ссылка ]

DONATE:

paypal.me/ELMN80R

Bitcoin: 1NYgPvcvBWuhGRewsLE4Scy1cbzwndh5hZ

2ND CHANNEL:

EP Vlogs: [ Ссылка ]

GEAR:

Camera: [ Ссылка ]

Camcorder: [ Ссылка ]

Tripod: [ Ссылка ]

Microphone: [ Ссылка ]

Cheap Mic: [ Ссылка ]

Old Headphones: [ Ссылка ]

New Headphones: [ Ссылка ]

Headphones for Music: [ Ссылка ]

Editing Software: [ Ссылка ]

Photoshop: [ Ссылка ]

MUSIC:

Intro/Outro Music: Burnt - Jingle Punks