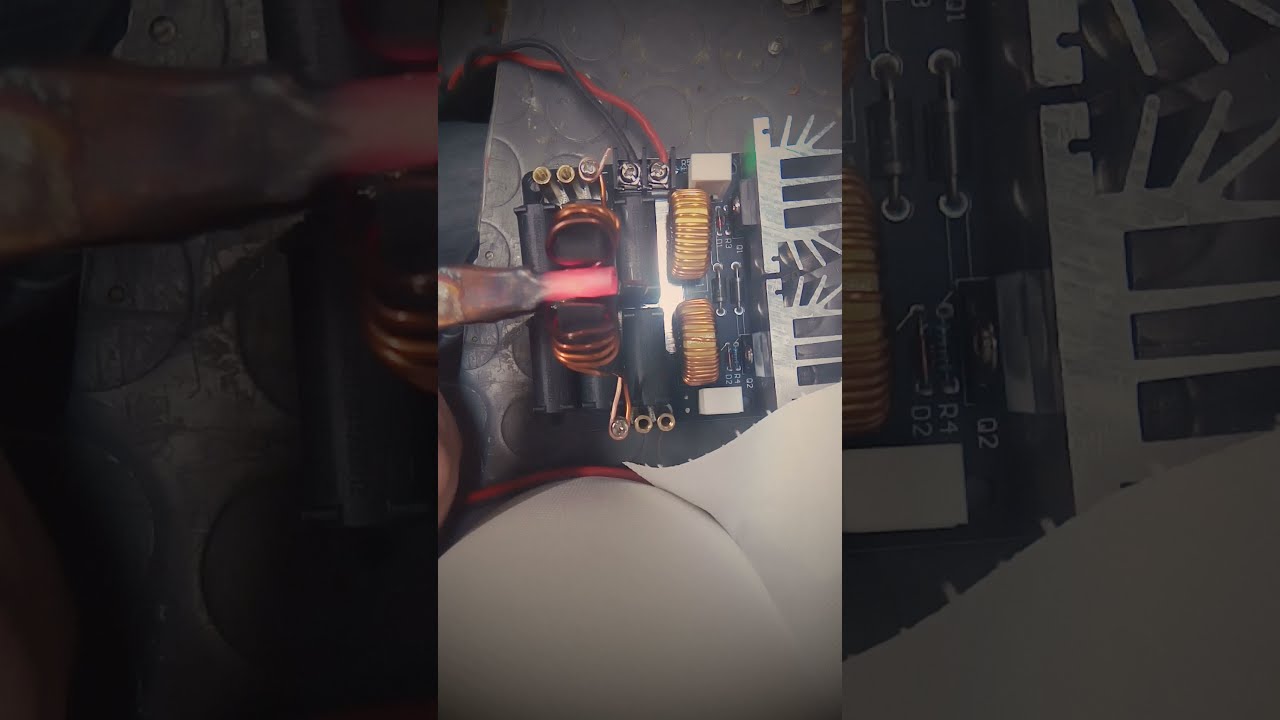

Testing flux concentration using a gapped toroid in order to silver solder copper, brass and stainless steel.

Non ferrous metals need special setup in order to efficiently heat them using induction, i used the cheap 1Kw ZVS induction heater sold almost everywhere.

Use a 50mm OD diameter toroid capable of high flux without saturating like those used in output filters of high power switch mode power supplies.

30mm will also do the job but i will eventually use a 50mm OD one in order to fit 3-4mm copper tube with water circulation for cooling.

The power used was 120W idle (30v@4A) and 225-300w (30V@7.5 - 10A) max when loaded (as the copper was getting hotter, current was decreasing), watch the green led reflection on the upper mosfet's heat sink in order to see how long it took to heat the end of a large copper crocodile used to connect a car battery.

Probably 24V would be a better choice if you plan to heat the part for longer period of time because judging from the color of the heated copper it would probably melt in 10 seconds, watch at the end of this shot video the color changing from dull orange to bright orange.