When you think about repairing roads the right way, this can mean many things. The focus points we will be covering in this article is on the importance of the Iron Works reinstatement system. So currently, there is an issue or ongoing challenge around the country regarding this. Many, many local authorities are reporting challenges with failing ironworks.

So it's crucial we take a step back and understand the reason for those failures. Leading of the back of part 1 we discuss all the other elements of this completely cold applied ironwork.

As soon as you open an ironwork before it's fully cured, you will get early compression in the bedding mortar, which results in movement of the cover. From there on, the situation only goes downhill.

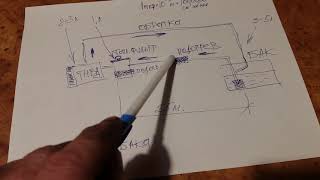

So what Meon has developed is a solution that can help to improve ironwork installations for years to come. Our Magma system goes right from the foundations through to the carriageway wearing coarse.

When looking at the foundation of the older chambers built with brick, there's often a very sound and secure structure which would have been there for many years. So when we come to put our ironworks on top, it's really important we ensure that we have a maximum of 25 millimetres of bedding material.

Additionally, if there are any broken bricks in that top course, it's important that we either repair the missing brick or take that top course of bricks off and build up the structure using a Shimpack / RoadShim system.

The road shim system does three things. Firstly it helps you to get the correct bedding mortar depth underneath your work. Secondly, it helps to improve the structural strength of the top of the chamber, which helps to bond the brickwork together. And thirdly, which is a key point when it comes to looking at doing a long term fix, the Shimpack system acts as an impact absorption system.

When you've got maybe three or even four layers of the Shimpacksystem, as shock waves come down from cars and heavy goods vehicles, the Shimpacksystem is constructed using a certain amount of cellulose-based content, and it has a certain amount of absorption capacity. That then absorbs some of that impact and it through the layers and therefore minimising the shock waves go directly either down through the chamber structure or back up through the bedding mortar.

Then we have the bedding mortar itself. It is a two-part bending mortar system that is a polymer modified cementitious product that is going to give you guaranteed performance and strength.

This material is going to achieve 40 newtons per millimetre squared within three hours of placement and is open to traffic time. The material then goes on to achieve 65 newtons per millimetre squared after 28 days.

Guaranteed performance can be achieved by using the two-part system. In addition to a very high compressive strength, it's also got very good tensile strength. Where you've got an ironwork in a high-stress location, which could be on a roundabout, bend, or a junction, you have a lot of horizontal and shear stress to the road wearing course. This is typically where vehicles are accelerating, braking and stopping at a location. The nett result is that the forces on the ironwork are more than just directly down in compression, but also sideways. Therefore you need a bedding mortar that has some good tensile capacity.