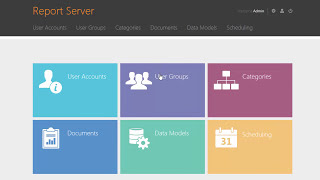

ANOTHER LINE TESTED AT OUR FACILITIES BEFORE SHIPMENT TO CUSTOMER!

r-PET Sheet - Direct process AMUT & EREMA combined technology

From 100% post consumer PET bottle flakes to food grade single layer sheet

Final Product:

• Net Width = 1.600mm (62”)

• Thickness Range = from 0,15mm to 1,5mm (12th to 60th)

• 1.600 to 1.800 kg/h

High V viscosity level

NO IV DROP DURING THE PROCESS

FDA and EFSA approval for food contact application

ADVANTAGES OF AMUT-EREMA TECHNOLOGY

- High-quality PET sheet produced using 100% bottle flakes from post-consume with FDA and EFSA certification.

- AMUT-EREMA system features a decontamination /dehumidification process (approx. one hour time) which totally extracts the volatile contaminants still present in the flakes, thus making the sheet quality better than any dryless co-rotating system.

- Production of perfect, non-fragile sheet without facing any IV (Intrinsic Viscosity) drops in production and no restrictions on thickness. Test with 1.5 mm-foil thickness.

- Possibility to reduce the thickness of thermoformed items.

- No restrictions on quantity of recycled material coming from the thermoforming process. The zero-drop in viscosity grants the possibility to reprocess the thermoforming skeletons of the PET sheet produced on the AMUT-EREMA line, creating an endless process of production starting from the first sheet produced on this equipment.

-Effective energy saving technology with a very low energy consumption.

Mailto: info@amut.it

![НЕ ВЫБРАСЫВАЙ диодные ЛАМПЫ это Простой способ их восстановить и использовать [Компанец ДА]](https://s2.save4k.su/pic/yXcC3NY9bCc/mqdefault.jpg)